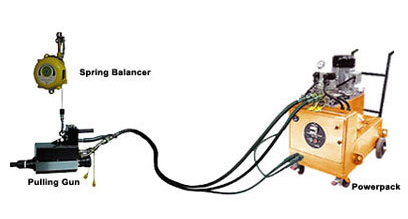

Continuous Hydraulic Tube Puller |

| We are offering Continuous Hydraulic Tube Puller |

|

Features :

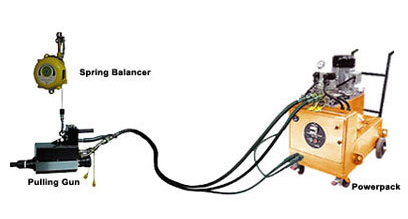

- Pulling gun communicates with powerpack via DC remote control. This ensures safely and eliminates the need of electrical cord between pump and gun that ohter manufacturers provide.

- Available with a choice of Electric - TPP System or Pneumatic - PPP System for hazardous, explosive working environments.

- Microprocessor controls on powerpack and gun ensure trouble free life.

- Removes tube without any damage to tube sheet.

- Low setup time and ease of operation.

- High power & High speed automatic cycling, for highest speed of pull available worldwide.

- Auto switchover from low pressure high flow to high pressure low flow on load and again back to low pressure high flow when load is released.

- Automatic slow start feature to minimize risk of breaking tubes and to conserve consumables.

- Compact design of Powerpack and Gun.

- Interchangeble pulling guns with same Powerpack. 15 ton gun for light duty high speed work, 30 ton gun for heavy duty tube pulling and 45 ton gun for tubes upto 3" O.D.

- Totally stainless steel construction body of powerpack for longer corrosion free life.

- Pulls up to 3" OD tubes continuously, pulls up to 4" O.D. stub.

- Low maintenance cost and worldwide availability of components.

- Significant saving of time and money over conventional system.

- Unit is portable with handle and mounted on four wheels for easy handling.

- Unit wil pull tubes continuously through the gun effortlessly, needing only one man for operation.

|

|

| |

| SEQUENCE OF OPERATION

|

|

|

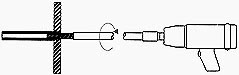

| A) Thread mandrel into tube with Impact Wrench |

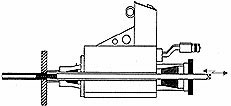

B) Mount Pulling Gun onto mandrel.

Automatic Slow Start to first to break expanded joint. |

| |

|

|

|

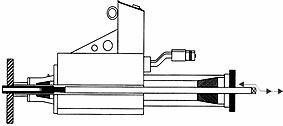

C) Switch to Auto Cycle by pressing 'AUTO' button till tube is completely removed. Gun will continue to cycle till one of the other buttons is pressed. When the tube is free, a tool can be inserted into the jaws to enable the tube to be pulled by hand. |

Unscrew mandrel from pulled tube

and proceed to next tube. |

|

| |

| TUBE PULLING POWERPACK - SPECIFICATIONS |

Note : Max. Working Pressure 350 bar. All Powerpacks

supplied with 5mtr long hydraulic hoses. |

Model |

Motor |

Volts / Phase |

Power |

Oil Tank Capacity |

Net Wt. |

Dim. |

Air Supple |

Hyd. Hoses Size x Length |

hp |

litrs. |

Kgs. |

mm |

inch x mtrs. |

TPP-50 |

Siemens |

415/3 |

5 |

90 |

220 |

1200 x 750 x 990 |

- |

1/2" x 5 & 3/4" x 5 |

TPP-75 |

Siemens |

415/3 |

7.5 |

138 |

270 |

1225 x 775 x 1015 |

- |

1/2" x 5 & 3/4" x 5 |

TPP-30 |

Siemens |

230/1 |

3 |

12 |

42 |

500 x 410 x 750 |

- |

1/2" x 5 & 3/4" x 5 |

PPP-50 (Pneumatic) |

Gast |

- |

9 |

90 |

220 |

700 x 560 x 480 |

180CFM AT 7 BAR |

1/2" x 5 & 3/4" x 5 |

|

| |

| HYDRAULIC TUBE PULLING GUNS - SPECIFICATIONS |

|

Note : All pulling guns are supplied with Forward,

Reverse, and Auto Cycle Switches. |

Gun Model |

Pulling Capacity |

Max. Tube O.D. Thru Gun |

Stub Pulling Capacity |

Weight |

Free Pulling Speed (meter/mim) with |

tons |

inch |

inch |

kgs. |

lbs. |

TPP-50 |

TPP-75 |

TPP-30 |

PPP-50 |

HPG-15 |

15 |

1 |

1.1/2 |

26 |

57 |

5.2 |

8.4 |

1.8 |

5.6 |

HPG-30 |

30 |

1.1/2 |

3 |

38 |

84 |

3.0 |

3.7 |

2.4 |

3.5 |

HPG-45 |

45 |

3 |

4 |

78 |

172 |

2.0 |

2.7 |

2.0 |

2.3 |

|

| |

|

|

| Next |

| |

|

|

Download PDF Send Enquiry Download PDF Send Enquiry |

| |

Communication Details

Address : 107, New Modella Indl Estate, Padwal Nagar, Wagle Estate, Thane (W)-400604

Maharashtra, INDIA.

Phone : +(91)-(22 )- 67257869 / 25834539 / 9769445455 / 9930224880

Email : response@tuberemovaltool.com